In the dry-mix mortar industry, the performance of redispersible polymer powder (RDP) directly determines the bonding strength and flexibility of tile adhesives, exterior wall putties, and thermal insulation mortars. As the source of RDP production, the physicochemical properties of VAE emulsions form the cornerstone of all these properties. Today, we will delve into two specialized VAE emulsions designed specifically for RDP production—DiverSol 628 (VAE CW40-758) and DiverSol 688 (VAE CW40-718).

1. Balance between High Solids Content and Rheological Properties

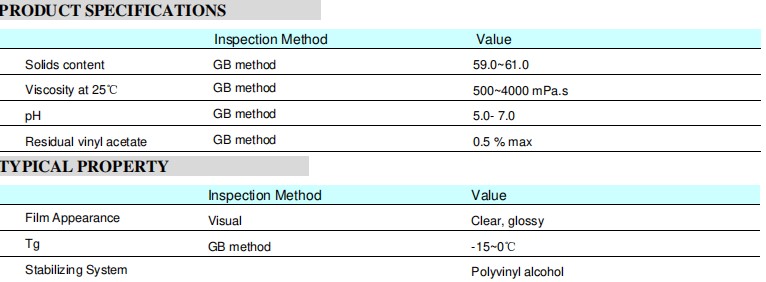

For RDP (polymer powder) manufacturers, spray drying is the most energy-intensive process. The solids content of the emulsion raw materials directly affects production efficiency and energy costs. DiverSol 628 and DiverSol 688 demonstrate extremely high industrial economics in this regard.

In the VAE emulsion field, a solids content of around 60% is considered high. This means that the amount of water that needs to be evaporated during the spray drying process is significantly reduced. Compared to conventional 55% solids content emulsions, using the DiverSol series not only significantly reduces heat consumption but also substantially increases the unit output of spray towers.

Besides solids content, viscosity is crucial for atomization performance. DiverSol 628/688 have a viscosity range of 500 ~ 4000 mPa·s (25℃). This wide viscosity range, combined with its excellent flow properties, provides powder manufacturers with a wide process window:

Furthermore, both products use polyvinyl alcohol (PVA) as a protective colloid system. This system is standard in RDP production because polyvinyl alcohol not only stabilizes the emulsion but also acts as a protective film during the redispersibility of the adhesive powder, preventing the powder particles from clumping in water and ensuring rapid dispersion of the final dry mortar after water addition.

2. Differentiated Formulation Strategy Based on Tg Value

Although DiverSol 628 and 688 are highly consistent in their basic physical properties (appearance, solid content, viscosity, pH), they take two completely different technical directions in their core thermal performance indicator—glass transition temperature (Tg), targeting "rigid" and "flexible" applications respectively.

2.1 DiverSol 628: High Tg Leads to Rigidity and High Strength

♣ Tg Range: 10 ~ 20°C

♣ Technical Characteristics: A Tg higher than room temperature means that the movement of polymer molecular chains is restricted after film formation, resulting in a film with higher hardness and cohesiveness.

♣ Application Advantages: RDP produced using 628 is more suitable for applications requiring high bond strength and surface hardness. For example:

2.2 DiverSol 688: Low Tg provides flexibility and crack resistance.

♣ Tg range: -15 ~ 0℃

♣ Technical characteristics: Significantly lower Tg than room temperature, the film is in a highly elastic state after formation, the film is soft, and has excellent elongation.

♣ Application advantages: RDP produced using 688 has its core selling points in flexibility and weather resistance. It effectively absorbs the deformation stress of the substrate, suitable for:

3. Industrial Compatibility and Green Environmental Protection

In actual industrial production, VAE emulsions not only need excellent performance but also must possess good "compatibility," meaning they must be compatible with other raw materials.

3.1 Broad Chemical Compatibility

DiverSol 628/688 were formulated with the complexity of downstream applications in mind. These two emulsions typically exhibit good compatibility with various thickeners, plasticizers, solvents, and fillers. This is crucial for RDP manufacturers, as anti-caking agents or other modifying agents are often added to the emulsion before spray drying. Good compatibility ensures the homogeneity of the mixture, preventing stratification or flocculation.

3.2 Environmental Protection and Aging Resistance

With increasingly stringent GB standards for the environmental protection of building materials, the environmental properties of raw materials have become a critical indicator.

3.3 Storage and Handling Guidelines

While the product boasts excellent performance, proper handling is equally important. Due to the presence of trace monomers, it is recommended to handle the product in a well-ventilated environment and wear protective equipment. Storage temperature should be controlled between 5°C and 40°C; freezing is strictly prohibited. It is particularly important to note that if the product has undergone long-distance transportation or long-term storage (shelf life 6 months), it is recommended to filter and stir before use to eliminate any potential lumps or crusts.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com