Polyvinyl alcohol (PVA), an indispensable water-soluble polymer material, is used in a wide range of fields, including construction, textiles, papermaking, and chemicals. Among the many PVA specifications, mesh size, or particle fineness, is a key factor in determining processing efficiency and final product quality.

1. Mesh Size Basics: A Measurement of Particle Size

Mesh size is a unit of measurement for powder particle fineness. It refers to the number of holes in a sieve per inch. The smaller the mesh size, the larger (coarser) the particles.

2. Introduction and Application of PVA Specifications of Different Mesh Sizes

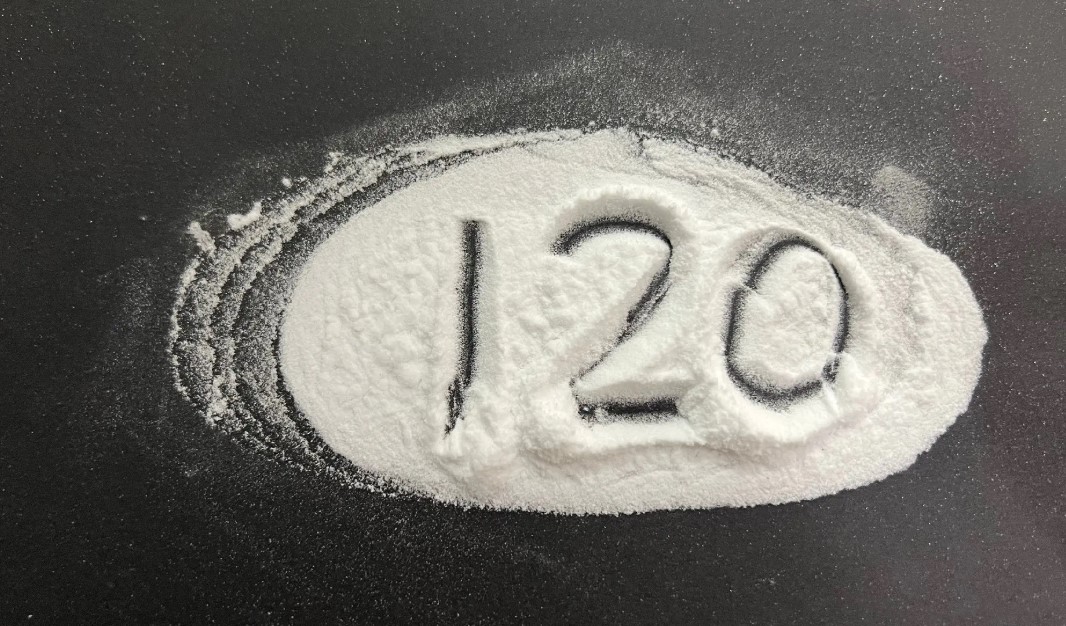

| Mesh Size | 20 mesh(Polyvinyl Alcohol 0588) | 120 mesh (PVA 088-05S) | 200 mesh (POVAL 22-88 S2) |

| Photo |  |

|

|

| Bulk Density | Relatively high | Medium | Relatively low (fluffy powder) |

| Key Features | The largest particles have the lowest surface area. This dissolution process is the slowest, but dust generation during operation is minimal; it is also known as a "low-dust" or "dust-free" grade. | This medium-sized particle size is the most commonly used grade in industry. It strikes a good balance between dissolution efficiency, ease of operation, and cost. | The extremely fine particles and maximum surface area ensure the fastest dissolution and the best dispersibility. |

| Applications |

Dry-mix mortar for construction: Coarse-grained PVA, as a binder, is less likely to form high-viscosity clumps during initial mixing, allowing for better dispersion in other components (such as cement and sand). It also produces minimal dust, improving the on-site construction environment.

Specialized slow-release adhesives: In certain specialized construction mortars or adhesives, PVA needs to dissolve slowly to provide lasting adhesion.

Preventing rapid thickening: Suitable for formulations that require prolonged mixing and where rapid thickening of the solution is undesirable. |

Conventional adhesives: Used in the manufacture of common water-based adhesives such as wood glue and paper glue.

Textile sizing agents: Prepare sizings at standard temperatures and times to meet the sizing requirements of most textiles.

Emulsion polymerization protective colloids: Serves as stabilizers and protective colloids in the polymerization of emulsions (such as VAE and acrylic emulsions). They provide a sufficiently rapid dissolution rate without excessively increasing system viscosity, ensuring stability and particle size distribution during emulsion polymerization. |

High-end water-based coatings: Suitable for high-end paints and putty powders that require extremely high dispersibility and a minimum of residual particles.

Fast Preparation/Low-Temperature Dissolution: Fine powder ensures rapid and thorough dissolution of PVA at low temperatures or under limited stirring capacity.

Water-Soluble Film: Used in the production of water-soluble packaging films requiring high transparency and good solubility, such as laundry bags and pesticide packaging.

Pharmaceutical/Cosmetic Excipients: Used in certain fine chemical applications requiring high precision. |

3. How to Make the Best Choice?

Choosing the right mesh size for PVA is essentially a trade-off between production efficiency, environmental safety, and product performance:

For those seeking dissolution speed and product fineness (e.g., coatings and films): 200 mesh is preferred.

For those seeking versatility, balanced performance, and moderate cost (e.g., conventional adhesives): 120 mesh is preferred(PVA 088-50S).

For those emphasizing operational safety, low dust generation (e.g., large-volume batching), or specific sustained-release requirements: 20 mesh is preferred(Poval 217).

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com