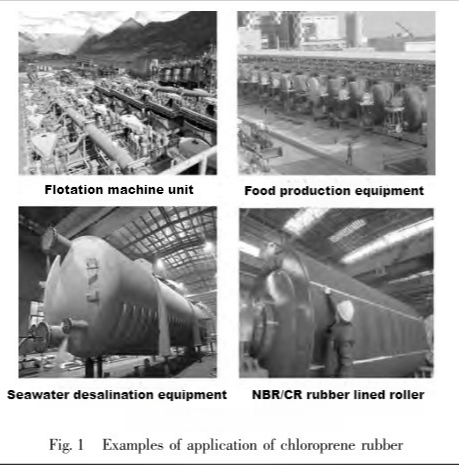

CR modified materials are really popular these days. A company called Shanghai Shuangpu Rubber Anti-Corrosion Lining Co., Ltd. has rolled out a bunch of different rubber linings, like CR, CR/NR, and NBR/CR. These products are proving to be quite useful across various sectors, including chemicals, electricity, steel, mining, and water treatment. You can see more about this in Figure 1.

Interestingly, Shanghai Shuangpu Rubber Anti-Corrosion Lining Co., Ltd. has done some side-by-side tests and discovered that certain fluoroprene rubbers made locally are performing on par with similar CR products that come from Japan and Germany. This is great news for the local industry, as it shows that we’re capable of producing high-quality materials that can stand shoulder to shoulder with the best from around the world. So, whether it’s keeping things from rusting or just making tough parts for machines, these rubber linings are definitely pulling their weight in various industries.

However, there are still few varieties of domestically produced fluoroprene rubbers, and there is no low-hardness fluoroprene rubber material. The existing main varieties, such as Chloroprene Rubber CR121, Chloroprene Rubber CR232, etc., are made of fluoroprene lining rubber sheets that are relatively hard, and the pre-vulcanized rubber sheets produced are very hard, making the pasting construction difficult. Further tests show that adding a large amount of softener to the formula can reduce the hardness, but when it reaches a certain amount, it will significantly affect the bonding strength. The production test also shows that the bonding strength of the cold-adhesive adhesive produced by domestic Chloroprene Rubber CR244 is completely up to the level of foreign Denka A90 Chloroprene Rubber and Bayprene 213. However, after being applied to the steel plate and rubber plate, the bonding retention time of the adhesive coating is significantly lower than that of the adhesive made of Denka A90 Chloroprene Rubber and Bayprene 213, and it is more obviously affected by the ambient temperature and humidity, which increases the difficulty of rubber lining construction of large equipment and increases the quality risk. It can be seen that there is still a lot of room for research and improvement in the material variety and application characteristics of domestic fluoroprene.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com